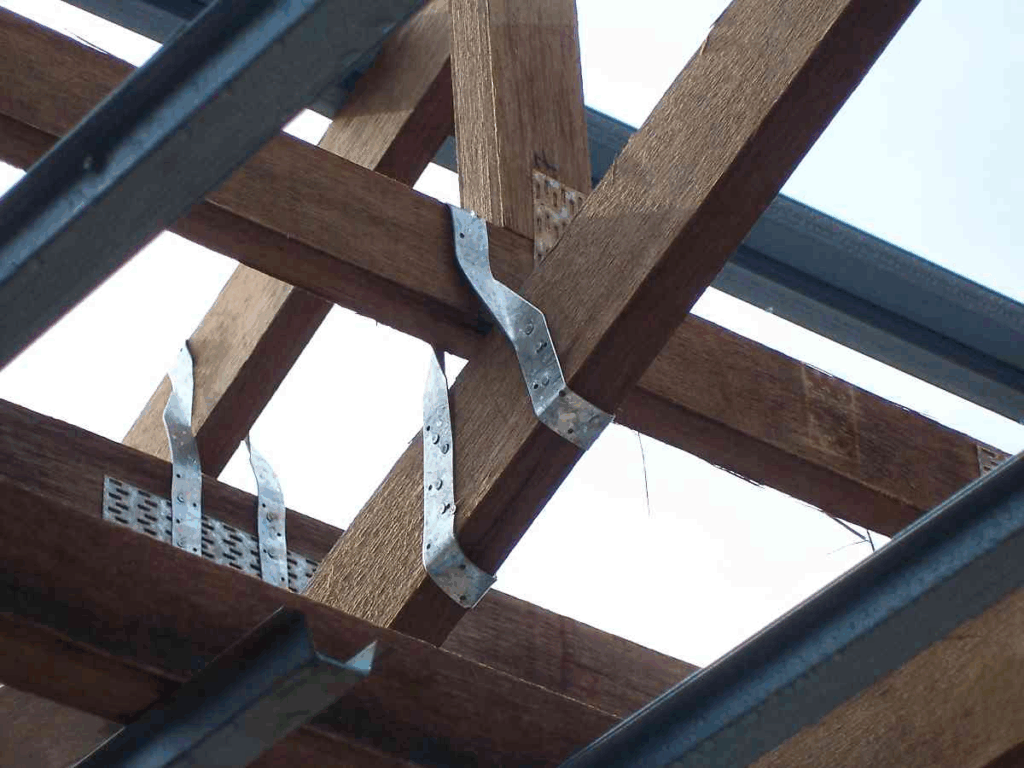

Hurricane ties have long been the standard when securing a roof to your double top plate in high wind zones. Pros pride themselves on efficiency, but hurricane ties typically require eight to ten nails for each strap. Even with a positive placement pneumatic nailer, that’s a lot of fasteners for one piece of hardware.

In areas prone to high wind events like tornadoes and hurricanes, code typically requires strapping. Even a Category 1 Hurricane has wind speeds that cause enough lift to rip the roof off a home in seconds. Using hurricane ties to create multiple points of shear resistance is an effective but time-consuming process.

Pros know that skilled labor is hard to find these days, with over 500,000 empty construction jobs in the United States last year. Installing multiple hurricane ties on each roof joist can significantly delay a construction project. Factor in less-skilled crew members, and you’re looking at delays.

New solutions on the market claim to provide the same level of protection against lift and shear in high-wind situations. Even with the market dominance of hurricane ties, some rumblings indicate a shift in the industry.

Is it time to reevaluate our reliance on straps to help create a continuous load path?

Creating a continuous load path is a crucial part of the engineering and construction process. Securing walls to the foundation and the top plate to the roof is just part of the solution. Beyond the scope of this article, continuous sheathing on the exterior of a build is just as essential for a wind-proof project. Other solutions exist for wall-to-foundation connections, but hurricane ties are time-tested for wall-to-roof use.

Installing hurricane ties properly into your roof joists and top plate can be time intensive. Using a palm nailer speeds up the process, but even then, it can take more than a minute per strap during framing. Even on a smaller residential project, all those hurricane ties add up. Add to that narrow spaces, awkward angles, and the potential for smashed fingers, and a different approach starts to sound like a good idea.

Come inspection time, even a few missed nails or improperly seated fasteners can lead to failure. Different models of hurricane ties may require more real estate on the lumber, complicating the process. Additional bulky hardware may also clutter up framing, making it more difficult for the other trades to complete their tasks.

In existing homes, hardening the roof system against increasing wind threats is possible, but challenging. Accessing joists and roof plates adequately enough to install more robust hurricane ties requires removing existing cladding and other materials. While the added strength may be worth the effort, the costs associated may not be.

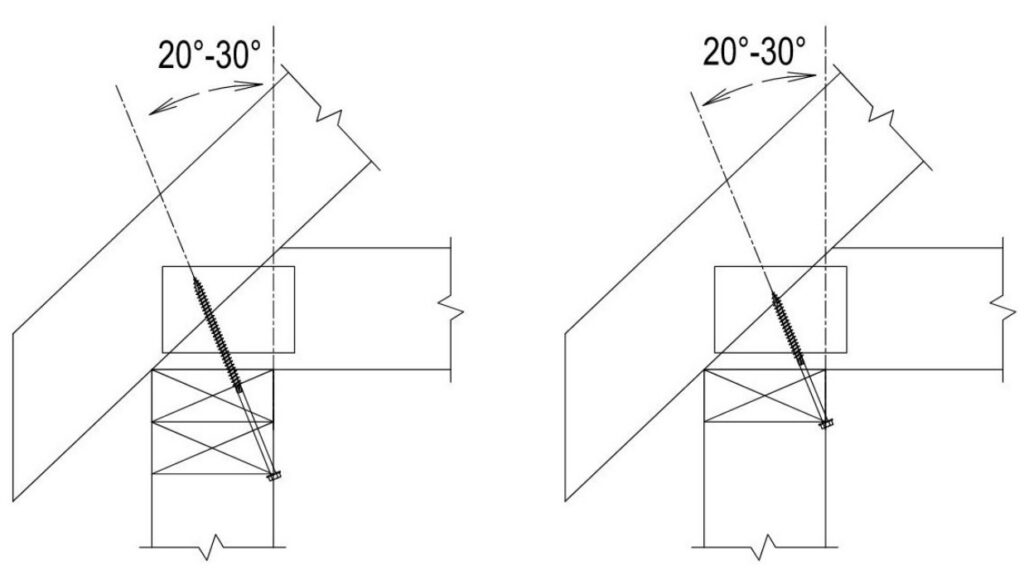

In recent years, structural screws appeared as a code-approved alternative to hurricane ties in many regions. These fasteners create a strong bond between the wall and roof plate that is difficult to replicate with a hurricane tie. The other significant difference between using structural screws and hurricane straps is speed. Reducing from ten or more joist hanger nails to one fastener is a massive time savings.

Next, consider how embedment affects how fasteners grip the wood members in a wall-to-roof application. Hurricane ties typically require nails driven perpendicular to the broad face of a joist. During a high wind event, uplift causes shear forces to work directly on the fasteners. With structural screws, one fastener creates a solid connection through all wood members in the wall, roof, and joist.

Grip-Rite® Structural Screws are rated for use in this application and are viable alternatives to hurricane ties in most regions. Available with a flat washer head or hex washer head, they’re engineered for heavy loads for deck to ledger assembly, multi-beam connections, and truss/rafter/joist to wall applications.

Hurricane ties and structural screws perform to code, which means they at least meet the baseline requirements in their areas. Before dropping metal hardware, though, check locally adopted codes to ensure compliance.

Head-to-head comparisons yield similar results, but the big differences come in cost and efficiency. Because of increased efficiency and less hardware overall, structural screws are a popular choice among builders.

Other key factors to consider:

Retrofit Applications – Hardening a structure against wind with structural screws requires less material removal than the same process with hurricane ties. Because of their smaller footprint, they’re a fast and effective solution.

Structural screws are a faster, more efficient method of securing the truss-to-wall connection. In spite of that, there are instances where hurricane ties still make the most sense.

Always cross-check fastener specs with local building codes to ensure compliance and reduce the chance of failing inspection.

In the battle between hurricane ties and structural screws, efficiency and cost are deciding factors. Replacing ten fasteners with one seems like an obvious choice. However, contractors will continue using hurricane straps out of convenience and habit.

Crews looking to balance quality, speed, and easy inspections should give structural screws a serious look. They help take the edge off of labor shortages and create a more secure continuous load path in the process. By creating a seamless connection between structural components, these fasteners allow a tighter bond that’s engineered to last.

Most contractors should be able to find structural screws in their local lumberyards or from suppliers. Sticking with hurricane ties won’t make your structure less wind-resistant, but it does reduce efficiency during installation.

Before making the switch, take time to evaluate your process, access, local codes, and timeline. If adopting a more efficient method makes sense, structural screws are the RITE choice.

Find out Where to Buy Grip-Rite products near you!