Builders in the residential space have discovered a hack in executing code-compliant wall assemblies: Grip-Rite ProWrap-SA. Balancing speed with increasingly strict energy and weather-resistive barrier code requirements means focusing on innovative building solutions.

Depending on where you’re building, different versions of building code apply. Since 2006, though, weather-resistive barriers have been specified as part of a wall assembly. They serve to protect against water intrusion from the outside and protect sheathing and stud walls from moisture damage.

Mechanically installed house wraps are specified on homes more than 60% of the time; however, they involve a lengthy installation process. Using a peel-and-stick house wrap saves time and labor and results in a tighter building envelope by reducing seams and penetrations.

Grip-Rite ProWrap-SA, a 2024 PTIA award winner, delivers advanced performance and easy installation to the building envelope. By offering efficient installation and critical code-compliant features, it’s an excellent choice to enhance your next build.

Meeting or exceeding the building code is about more than just passing inspection. Codes are updated every three years to adapt to changes in building science and mitigate climate risks. As mentioned, code compliance varies by state, and homes constructed under outdated guidelines are at greater risk. A recent report shows that only 31 percent of hazard-prone areas have adopted up-to-date codes.

States that implement current building codes must comply with standards regarding the performance of weather-resistive barriers.

From the 2021 IBC R703.2 Water-resistive barrier:

Not fewer than one layer of water-resistive barrier shall be applied over studs or sheathing of all exterior walls with flashing as indicated in Section R703.4, in such a manner as to provide a continuous water-resistive barrier behind the exterior wall veneer.

This standard requires builders to use a weather-resistive barrier directly over the exterior sheathing to protect against moisture. However, the code also suggests that No. 15 felt is an acceptable barrier. Compared against ProWrap-SA, it’s clear that the code favors the lowest common denominator.

ProWrap-SA builds upon the fundamental principles of the code, elevating them. Combining high drainability, permeability, and long-term durability, this self-adhering house wrap outperforms No. 15 felt at every turn.

The advanced membrane meets high drainability and vapor permeance. Water can’t move through the assembly from outside, and vapor from the interior dries to the outside. Similarly, air cannot move from the outside in, but it can move from inside out, protecting the wall cavity from moisture buildup.

Damage resulting from poor WRB performance can lead to material failure and mold, necessitating replacement or costly mitigation efforts. A properly deployed membrane can promote a healthier interior environment and prolong the life of your structure.

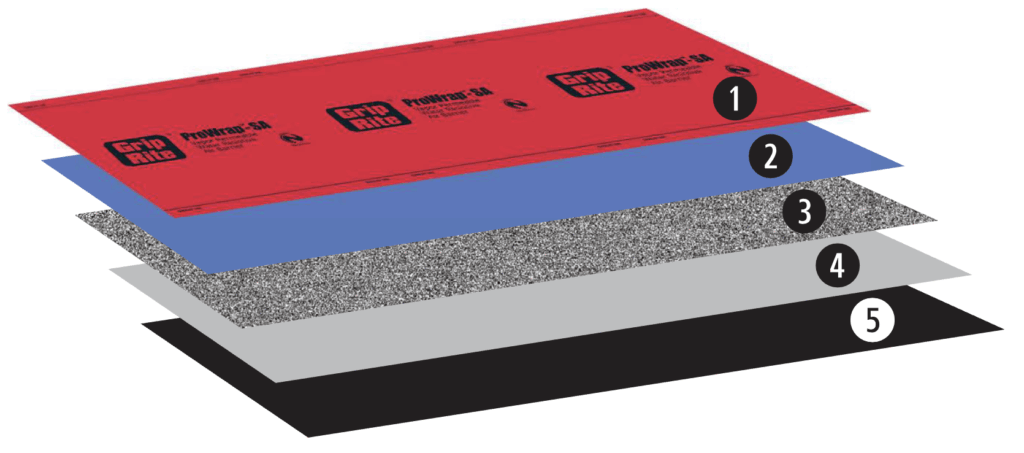

ProWrap-SA is a powerful addition to an efficient building envelope. The proprietary 5-layer construction method provides a durable and tear-resistant membrane. It repels bulk water intrusion and comes pre-printed with an overlap line for optimal performance. A pressure-sensitive butyl adhesive offers a secure, self-sealing bond on exterior sheathing, preventing air leaks around penetrations.

Installation is a simple peel-and-stick process that allows users a 30-minute window to reposition if necessary. Once a run is in place, using a hand roller creates a lasting bond that resists hydrostatic pressure and protects the built environment.

A self-adhering weather-resistant barrier is essential for a tight building envelope. To provide homeowners with the most benefit from their advanced air management systems, smart membranes are necessary. Depending on the climate, a wall assembly may experience moisture condensing on the outer wall, inner walls, or both as the seasons change. Drainability moves moisture away from the exterior surface, preventing issues caused by hydrostatic pressure. Vapor permeability allows moisture from within a wall assembly to pass through to the outer surface, where it can evaporate.

Comparing ProWrap-SA with No. 15 felt, the material specified in code, pros see a marked difference in performance.

A side-by-side comparison shows the differences:

| Characteristic | No. 15 Felt | Grip-Rite ProWrap‑SA |

| Vapor Permeability | ~5–6 perms (semi-permeable) | 60 perms (highly vapor permeable) |

| Air Leakage Rate | Not rated / Not an air barrier | 0.02 L/s·m² @ 75 Pa (ASTM E2178) — Air barrier compliant |

| Drainage Efficiency | Minimal — lacks an integrated drainage plane | Integrated drainage layer provides high drainage efficiency |

| Sealability Around Fasteners | Limited — no self-sealing capability | Excellent — self-seals around fasteners (meets ASTM D1970) |

| Weight per Roll | Typically 15 lb (36″ x 144′) = ~3.5 lb/100 sq ft | 19 lb (48″ x 100′) = ~4.75 lb/100 sq ft |

| Installation Technique | Mechanical fasteners and overlaps; may wrinkle or tear during installation | Primerless, peel-and-stick install; adheres in cold temps (≥20°F) |

Incorporating advanced materials into the building envelope increases energy efficiency and protects against premature degradation.

ProWrap-SA creates a continuous air and water barrier, preventing uncontrolled air exchange between the interior and exterior environments. This increases the R-value of the wall system. When paired with ProWrap® FLEX and Butyl flashing tapes for window and door openings, pros can create a consistently tight building envelope.

Labor shortages and high cost of materials mean that contractors are maximizing material and manpower on every job. Self-adhering WRBs are quick to install and don’t require special tools or large crews to work efficiently. Your crew won’t need compressors and nailers, just a knife and roller for installation.

The butyl adhesive backing ProWrap-SA doesn’t require the use of a primer and will install down to 20 degrees without loss of adhesion. Durable 5-layer construction won’t tear and adheres to most sheathing substrates.

Primerless installation on common materials like

As long as the material is dry and free from dust, ProWrap-SA provides superior performance and long-lasting protection.

Instead of requiring a whole installation crew, a two-person team can easily install ProWrap-SA with basic tools. No need for extra fasteners, pneumatic staplers, or nailers. The split-back plastic sheeting is easily separated from the adhesive backing and quick to install.

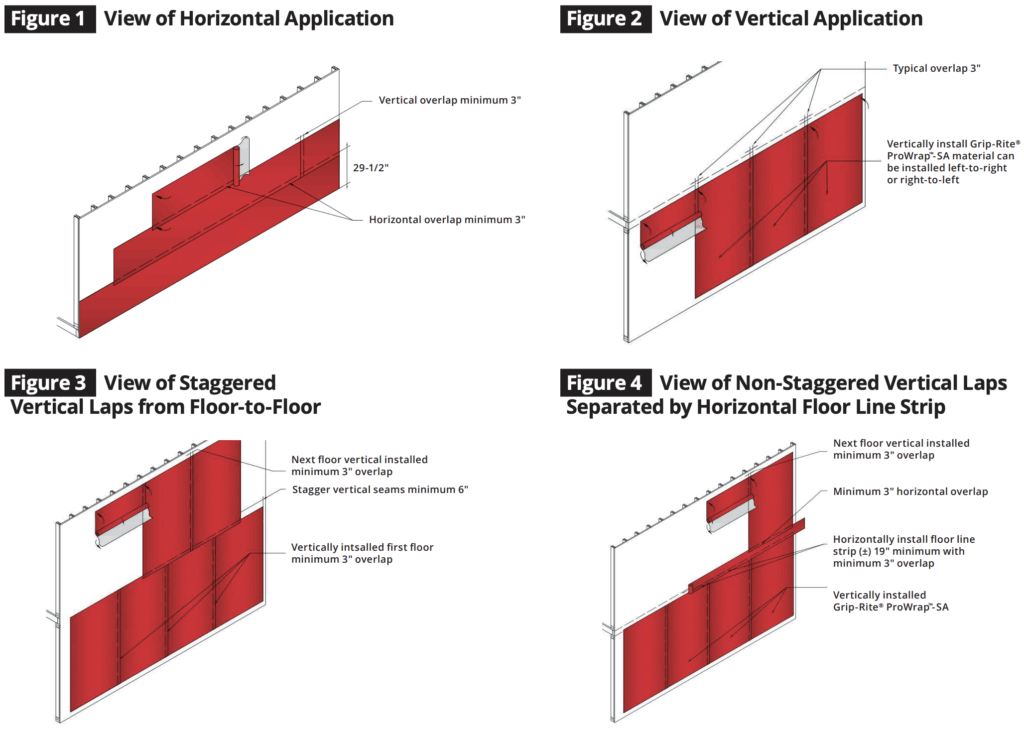

Grip-Rite ProWrap-SA may be installed in vertical or horizontal rows with a three-inch overlap to ensure water-tightness. Once applied, you should install the cladding as soon as possible, although it’s specified to withstand up to 180 days of UV exposure without degradation.

ProWrap tapes are ideal for use with the house wrap membrane as they preserve the continuous air and water barrier. FLEX is easily conformable to windows and doors and can be smoothed into hard-to-reach corners, irregular penetrations, and protrusions.

Make sure to follow all manufacturer recommendations for optimal performance and to maintain warranty.

Choosing a higher-quality house wrap translates to improved performance and long-term durability. Moisture is the biggest threat to tightly constructed projects, and ProWrap-SA keeps water and vapor moving away from the wall assembly.

Temperature Extremes

Contractors can install the membrane without primer down to 20 degrees with no cracking or reduced performance. It has been tested under AAMA 711 to identify any susceptibility in the material to extreme temperatures.

According to AAMA 711, Section 5.5, the material is exposed to extreme temperatures of 176°F for seven days. ProWrap-SA exhibited no visual damage and maintained adhesion on anodized aluminum.

AAMA 711, Section 5.6 tests the material under extreme thermal cycling, similar to what it would undergo during seasonal changes. Over 10 cycles of 8 hours at 120°F and 16 hours at -40°F, there was no visual damage and no loss of adhesion over anodized aluminum.

UV Resistance and Self-Sealing

According to AAMA 711, Section 5.4, the material exhibited no visual signs of damage and maintained its performance after 336 hours of exposure.

For a full breakdown of testing and performance data, check out the ProWrap-SA spec sheet.

ProWrap-SA is rated for use in many different types of wall assemblies. It can be safely deployed in residential, multi-family, and light commercial applications without compromising code compliance.

You may also use this product as part of a continuous insulation application as an outer layer on a rigid foam and sheathing product. Because of the self-sealing properties of the product, pros use it as part of a rainscreen system with furring strips.

ProWrap-SA represents a significant advancement over code-compliant No. 15 felt. A complete air, water, and vapor control system prevents unnecessary damage to wall assemblies by keeping moisture where it belongs.

Architects and designers can also find a 3-part specification document available on MasterSpec® for use in the design phase of construction.

If you’re ready to elevate your building projects, find out Where to Buy Grip-Rite products near you.