Contractors are always looking to find ways to boost productivity, and in today’s construction landscape, efficiency is more important than ever. A shrinking labor force and escalating material costs mean that faster completion times are necessary to keep business moving.

For high-volume builds involving thousands or tens of thousands of fasteners, even incremental time savings pay off. The team at Grip-Rite continually evaluates performance and develops new products to boost productivity on the job.

Whether through engineering new features or revamping existing features, engineers recognized that fasteners are an area where saving time on the job is still possible.

We’re taking a look at the top six fastener features that boost productivity around the jobsite. They increase drive speed, reduce misfires and jams, and help decrease waste simultaneously.

Driving fasteners consistently relies on the design, efficiency, manufacturing, and experience. Of these, we can’t control the user’s level of experience, so instead, we focus on creating consistency to boost performance.

For maximum consistency, we maintain tolerances that fall within spec on all our fasteners. Screws require more engineering than nails, and from the tip to the head are opportunities for enhancement.

Sharp points can cause splitting or damage to some wood materials, requiring pre-drilling for a smoother workflow. Unless a wood piece comes from the mill with fastener holes already, constantly switching between tools is cumbersome and slow.

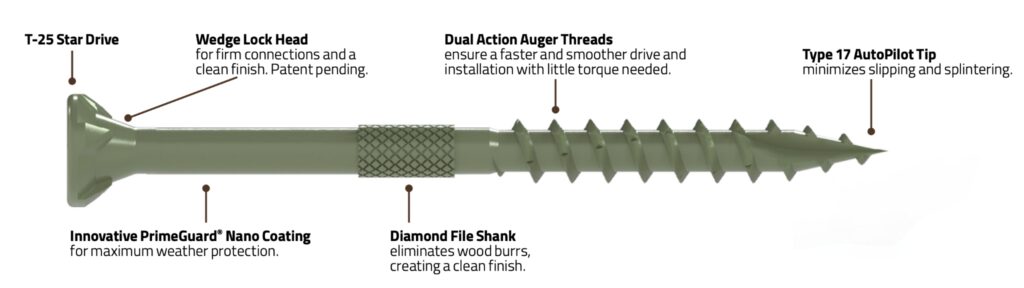

Grip-Rite wood and construction screws all feature a special tip that drives consistently in one shot. The T 17 tip features a cutout that acts like an auger, reducing the need for pre-drilling altogether. For composite materials, saw-like teeth help remove material that may cause binding or mushrooming in the final surface.

Threads should be sharp and evenly spaced to ensure smooth installation—coarse threads for wood, fine threads for metal, and hi-lo threads for composite or cement board materials. Inconsistent manufacturing methods result in uneven threads, which can slow productivity and damage the material.

The drive recess is where the tool tip connects to the fastener. It’s where the power from the tool transfers to the fastener, and a solid connection here helps boost productivity. Phillips drive was the standard for many years, but star drive and square drive are superior in most applications. They reduce slipping and camouts, and help keep fasteners engaged for higher torque and faster installations.

Product Example: Grip-Rite DeckForce® Exterior Screws are engineered with features that enable fast and consistent driving, resulting in less user fatigue and tool wear.

Hand driving fasteners at volume can be exhausting on long days, wearing out both the user and tool over time. Enter collated fasteners and compatible pneumatic or battery-powered tools that use compressed air or electrical power to drive screws and nails fast.

You can purchase a collated fastener for nearly any application on the jobsite.

Collated nails are more common than collated screws, and for good reason. Nails require direct force to install, while screws rely on rotational force (torque).

Common types of collated nails include roofing, fencing, siding, framing, and finishing.

Drywall and subflooring are the two most common applications where contractors use collated screws. Most commercial drywall screw guns either have attachments or are desiged for collated screws. Similarly, subflooring tools often have an extension and attachment for strips of screws.

One of the challenges of collation is that whatever is holding the fasteners in alignment can’t get in the way of installation. Over the years, four primary methods have emerged as the most effective for various applications.

Product Example: Grip-Rite 21⁰ Framing Nails are engineered for consistent, jam-free driving and a superior hold in framing and general construction applications.

Find out Where to Buy Grip-Rite fasteners near you.

Fasteners are designed with specific applications in mind, and the materials and coatings used are integral to that equation. With the right combination, you’ll experience fewer callbacks, leading to increased worksite efficiency. Additionally, coatings or application-specific materials are crucial to the longevity of a project where corrosion is a possibility.

Most coatings are for protection, but there are a few that make installs faster. Phosphate coating can speed up installation and provide enhanced grip in drywall applications. Some nails are also coated in vinyl, which acts as a lubricant during installation and can enhance grip in some use cases.

When installing fasteners in exterior settings or around water, they must be coated or made from corrosion-resistant material.

Common coatings include:

For general construction applications, carbon or alloy steel performs consistently in testing for both load-bearing and non-load-bearing applications.

For coastal applications, 316 Stainless Steel is the best choice. It’s naturally corrosion-resistant and approved for use around saltwater and harsh chemicals.

Product Example: Grip-Rite PrimeGuard MAX® Stainless Steel Fasteners are rated for use in coastal environments and guaranteed for the life of your project against rust and corrosion. They won’t scratch, chip, or lose their anti-corrosive quality over time.

Self-drilling and self-tapping screw tips are significant time savers on the jobsite. Most general construction screws come with a self-drilling tip standard, but in specific applications they’re essential.

For wood-to-wood applications, self-drilling tips eliminate the need for pre-drilling and reduce the risk of splitting. Consistent driving speeds and reduced torque during driving minimize wear and tear on tools, resulting in a clean, finished piece.

Wood-to-metal and metal-to-metal applications are more efficient with self-drilling or self-tapping screws. Self-tapping screws are particularly important when working with metal framing or HVAC systems, where a secure fit is essential.

Product Example: Grip-Rite Hex Washer Head Screws with Neoprene Washer are self-drilling screws designed for use in metal-to-metal and metal-to-wood framing and roofing applications. The T 17 point pierces through metal and wood without pre-drilling, and the neoprene washer provides a watertight seal.

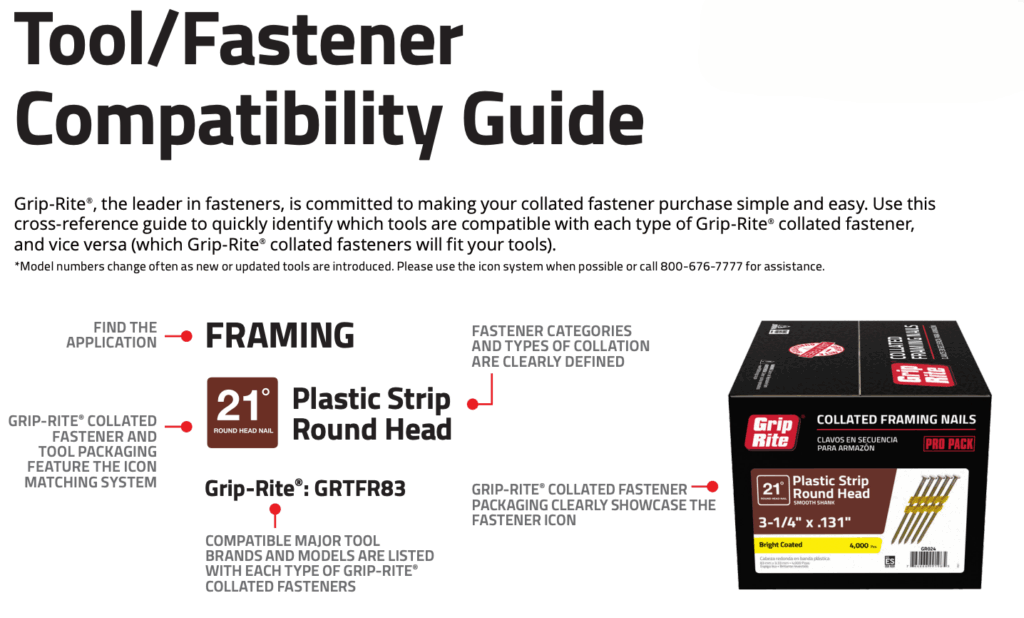

On a large jobsite, having the correct fasteners readily available reduces downtime and keeps your job on schedule. Grip-Rite makes this simple with our proprietary icon system and color-coded labels for different applications and coatings. On the label, you’ll also find required code approvals, tool compatibility, and whether the fastener is rated for use in treated lumber.

Instead of purchasing one-pound or five-pound boxes, consider Grip-Rite bulk tubs and contractor packs as an alternative. Easy-carry handles and resealable lids make them easy to move around the jobsite, protecting unused fasteners from the elements. Transparent plastic material lets you see at a glance if it’s time to reorder or head to your nearest Grip-Rite partner.

Keeping your job site organized and user-friendly for your crew is an underrated method to boost productivity. Having easy access to precisely what you need, without wasting time searching through stacks of boxes, means more time on the job.

Product Example: Grip-Rite bulk tubs are easy to carry, stack, and reseal for clean and organized storage.

Find out Where to Buy Grip-Rite fasteners near you.

Jammed pneumatic tools put a serious kink in your workflow. Grip-Rite collated fasteners are optimized for use in compatible pneumatic tools, and our compatibility guide gives you all the details.

Using incompatible fasteners can damage your tool, waste resources, and put deadlines at risk. Tools can fail to load, feed, or actuate properly when used with the wrong fastener. Through our Jam Free Guarantee®, Grip-Rite stands behind our collated fasteners for six months from the date of purchase.

Product Example: Grip-Rite Collated Framing Nails are designed for versatility and are compatible with most 21° pneumatic framing nailers (plastic collated) or 30° pneumatic framing nailers (paper collated). Packaged for the jobsite in clear plastic tubs, we also offer a Pro Pack of 5000 for larger projects.

With tight margins on everyone’s mind, using fasteners to boost productivity on the job makes sense. Choosing features that speed installation and longevity means faster installs and fewer callbacks, both good for your bottom line.

For professional-grade fastener options, Grip-Rite has a solution for you. Interior, exterior, hand drive, and pneumatic, our assortment is precisely what you need for your projects. Big or small, we help you get the job done right.

Find out Where to Buy Grip-Rite fasteners near you.