Sustainable building materials have driven innovation in the construction industry in recent years. With experts predicting 70% growth in new projects over the next 15 years, there is a significant market opportunity. The full economic impact of eco-friendly building solutions might be hard to see from a high-level view, but it’s worth a closer look.

Construction generates massive revenue, with a projected value of close to $14 trillion by 2027. Along with all that revenue, though, comes 37% of global carbon emissions. Through material fabrication, construction activities, and building operations, the industry’s carbon footprint is hard to miss.

Sustainable practices and low-carbon building processes are the focus of much of the industry. According to a United Nations Environmental Program study, three key strategies are shifting the landscape:

Decarbonizing the global construction industry serves as both an economic and ecological benefit. Through innovative materials and greater efficiency, projected growth will support a sustainable future.

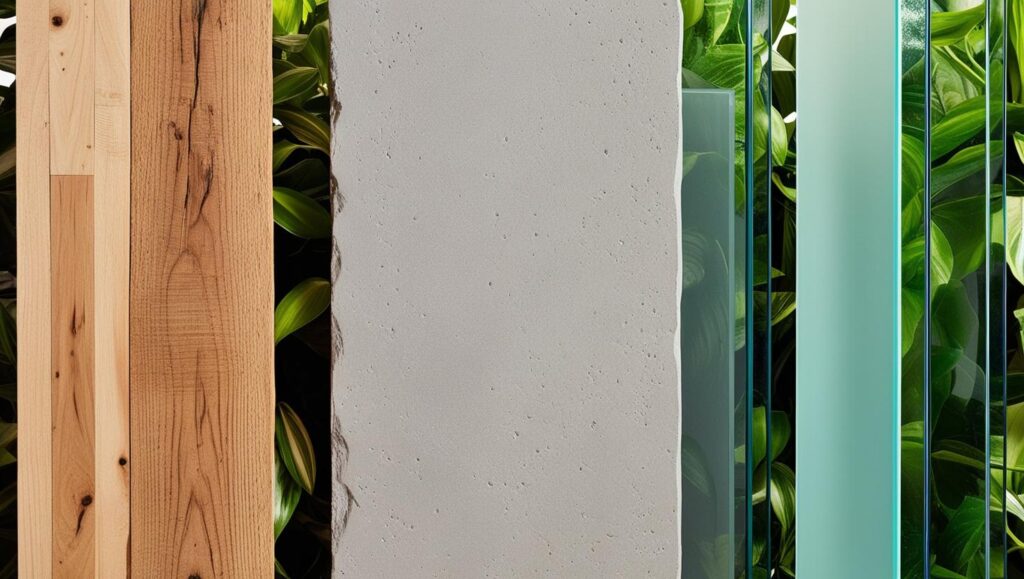

Eco-friendly building materials appear in nearly every product category. From framing and insulation to Eco-friendly building materials appear in nearly every product category. From framing and insulation to cement and weather-resistant barriers, low-impact products and manufacturing are common.

According to Renewable Energy Magazine, a sustainable building material meets specific criteria. To be classified as sustainable, a material must have/use:

Some of the most sustainable building materials incorporate bamboo, ceramics, reclaimed wood, and recycled steel.

Innovation in the conventional materials space also supports sustainable material practices. Non-traditional cement formulations, engineered wood, and recycled steel provide opportunities for buildings with a smaller carbon footprint.

Cement production is one of the biggest culprits of carbon release in the construction industry. Portland cement, the most common formulation, has a notoriously high carbon footprint throughout its life cycle.

Each step in the cement manufacturing process produces excess carbon, from converting limestone into calcium oxide to necessary fuel combustion. Seven percent of global carbon emissions derive from portland cement. Major producers like China show few signs of slowing, and the environmental impact is significant.

Despite how it seems, reducing the carbon footprint of cement and concrete-based products is possible. Incorporating bio-based alternatives derived from agriculture and forestry reduces carbon emissions substantially. Other materials like low-carbon lime and polymers also have potential use in the industry.

One of the most significant innovations is using magnesium oxide (MgO) in cement production. The unique chemical composition of magnesium-based cements makes them sustainable. In contrast to portland cement, these materials are lighter, stronger, more durable, and have notable fire resistance.

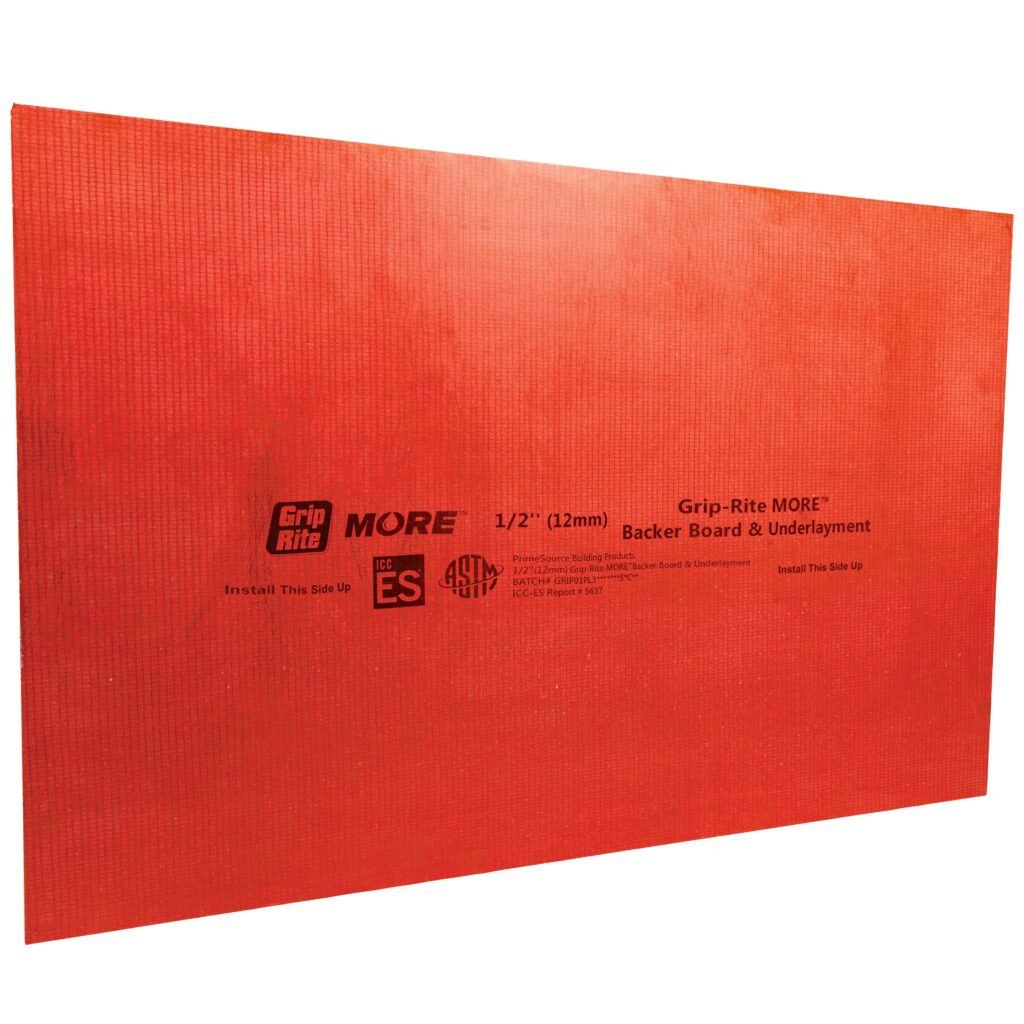

Products like Grip-Rite MORE™ backer board and underlayment impact the environment by providing a reasonable alternative to less sustainable options. With enhanced flexural strength, fire and pest resistance, water resistance, and no quartz-silica dust, this building solution is a step in the right direction.

Beyond the environmental impact of low-carbon cement alternatives, consider the economic impact. After a disaster, replacing damaged materials is costly and has become increasingly so in recent years. MgO cement resists many environmental challenges that make replacement necessary in other products.

Many other building material alternatives have carbon-neutral and carbon-negative properties.

Incorporating these materials into building projects is easier than ever, and many building codes require more efficient and resilient building practices.

Using sustainable materials in a building project is about more than just reducing a structure’s carbon footprint. They also impact the environment in the long term and contribute to significant operational cost savings.

Many sustainable products are more energy-efficient than conventional alternatives. They’re often more durable across their lifecycle, reducing premature repair or replacement. From extraction to disposal, they have a smaller impact on the surrounding ecosystem.

Other benefits include:

Increased energy efficiency and low thermal conductivity from earth and mineral-based solutions create economic savings.

Other benefits include:

Sustainable construction materials’ environmental and economic impacts strongly incentivize their use.

Grip-Rite recognizes the importance of using sustainable building materials. With Grip-Rite MORE™ backer board and underlayment, you won’t have to sacrifice performance to do the same.

Lightweight and strong, our backer board brings future-focused materials to your wet room projects.

For more information on bringing Grip-Rite MORE™ to your customers, contact our product specialists for a demo.