In the professional contractor’s toolbox, the fastener is king. No matter the job, if you’re joining materials, the fastener makes all the difference.

Even seasoned pros have made one or more of these fastener mistakes. Whether out of convenience or simple error, grabbing the wrong box off the shelf can have significant consequences for your bottom line, and even your reputation.

We’re taking a closer look at these five common fastener mistakes that take a bite out of your wallet so you can avoid them in the future.

Using the wrong fastener for the job can lead to a weak, ineffective connection, early fastener failure due to corrosion, and even catastrophic failure. While some of the consequences are surface-level, some may lead to expensive repairs or total replacement. Skimping on fasteners to save money can lead to more costly issues down the road.

To avoid this mistake, it’s essential to know the main differences between fasteners. While most pros have the experience to know, the details aren’t always top of mind when the apprentice is at the lumberyard.

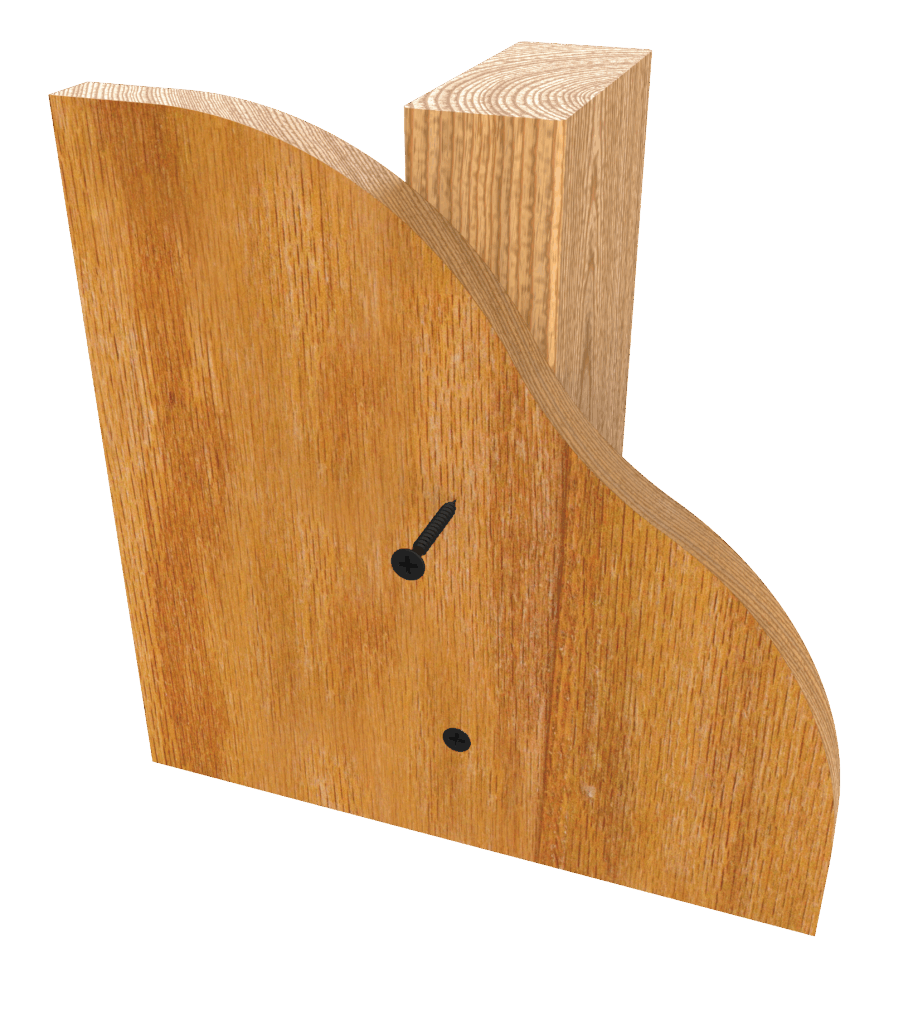

Wood-to-wood fasteners are commonly sold as construction screws or general construction screws. They typically feature coarse threads and have a sharp or self-drilling point, making pilot holes unnecessary. Coarse threads grip wood fibers without stripping out, creating a strong connection between the shank and the material. Only use structurally rated fasteners in load-bearing applications.

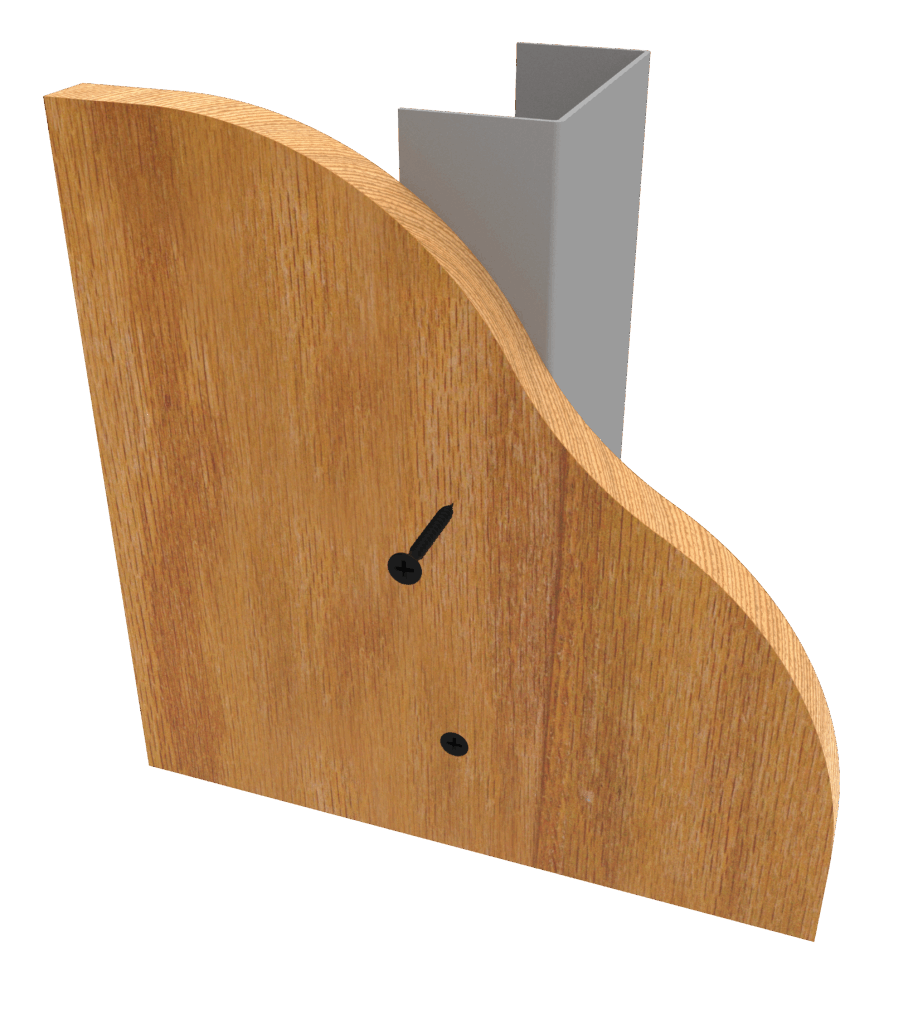

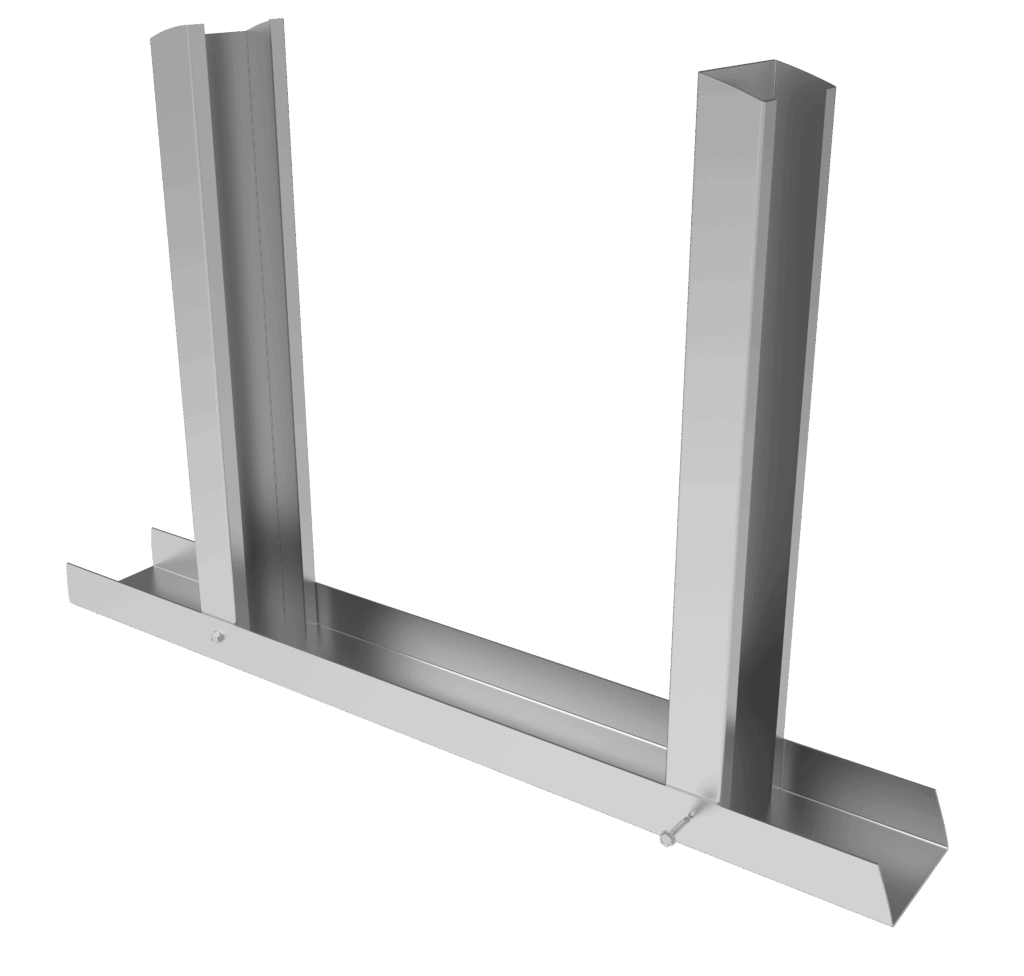

Wood-to-metal fasteners are designed with special features that help preserve the threads, ensuring a secure connection. Generally, screws intended for use in metal have finer threads than those designed for use in wood. Hi-lo threads are a good compromise as they engage both wood and metal. Frequently used for hanging drywall in metal studs, fine thread drywall screws are the most common.

Metal-to-metal fasteners typically feature a self-drilling point and fine threads, allowing for secure attachment. They’re also available with self-tapping threads for a more secure fit. Because some metals are reactive with others, they’re frequently coated or plated to prevent galvanic corrosion. Zinc, phosphate, nickel, and chrome are all used as barriers in these cases.

Bright or uncoated fasteners aren’t protected from environmental moisture and will rust or corrode.

Zinc-coated or plated fasteners offer varying levels of protection against corrosion. Electrogalvanized and hot-dipped galvanized are the most common applications you’ll see.

Polymer or ceramic coatings offer superior protection from corrosion. Grip-Rite PrimeGuard® is a perfect example of this type of coating. Beyond protecting the fastener and material, they’re also backed by up to a limited lifetime warranty.

Stainless Steel isn’t a coating, but it offers the most robust corrosion resistance and can be used in coastal settings to build docks, decks, and other outdoor projects. Read more about screw coatings at our Knowledge Center.

General construction fasteners are meant for non-load-bearing applications where they won’t be exposed to shear or tensile forces. Shear force is at a 90-degree angle to the fasteners, and tensile force is along the shank.

Structural fasteners are specifically designed to withstand these forces and shouldn’t snap or stretch when used within their load rating.

Pro Tip: Match the fastener to load, material, and environment.

Working in a professional setting means using tools calibrated for experienced users. Before beginning each workday, it’s good practice to check items such as PSI on compressors and depth on pneumatic tools. Further, some fasteners aren’t rated for use with impact drivers and can fail when used with the wrong tool.

If you’ve got a new crew member on the job or are training an apprentice, it’s a good idea to highlight the importance of proper driving and installation.

Over-driving occurs when a fastener is seated too deeply in the material due to installation forces. Nails and screws are both susceptible to this type of failure. It results in stripped recesses, damaged materials (such as torn drywall paper and shingle tear-through), and damaged tools.

Under-driving occurs when a fastener isn’t driven with the appropriate amount of force. This can also lead to camouts while driving, a loose hold between substrates, and damaged materials.

This mistake could happen to anyone when there’s pressure to meet a deadline. While blazing through a sheet of drywall or fence pickets is impressive, it’s harder to ensure accuracy at high speed. Poor fastener placement can result in damaged material, cracks in wood or masonry, and a haphazard appearance.

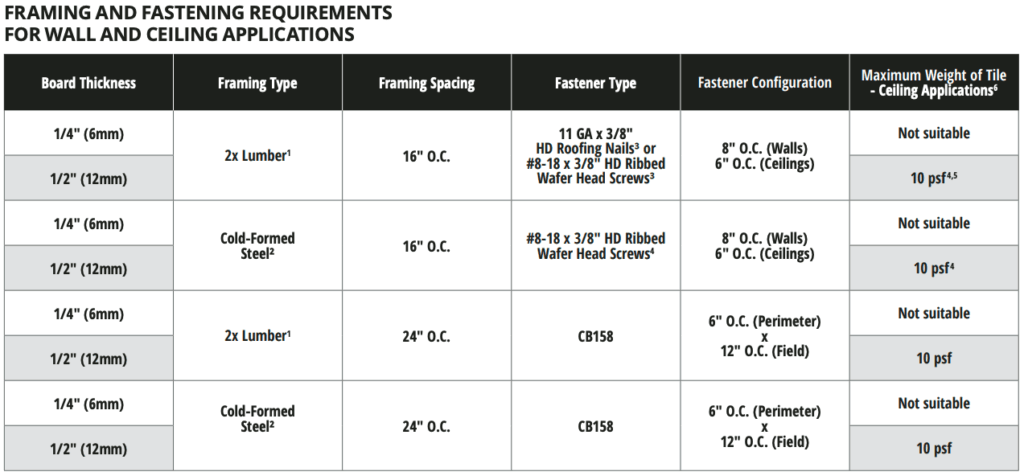

Many manufacturers include spacing recommendations with the installation instructions of their product. Others include a fastener pattern on the product or have a template to follow for efficient driving.

Take, for example, Grip-Rite MORE™ backer board and underlayment. In the installation guide, we’ve included recommendations for different stud distances, types, and indications for ceiling or wall applications.

Of course, using the right fastener makes all the difference here. For this application, we’ve spec’d Pro-Twist cement board screws. They have the perfect combination of a flat head with nibs and hi-lo threads for a strong connection.

Our next fastener mistake involves selecting low-quality or compromised fasteners for your projects. Budgets are what they are, but cutting corners on which fasteners to use can have major consequences. Work with trusted suppliers and manufacturers like Grip-Rite for quality you can trust for any application.

Trying out a new manufacturer or supplier can be tempting when costs start to climb, but be wary. Inspect your inventory when it comes in, ask other contractors, and prioritize quality over cost.

Find out Where to Buy Grip-Rite fasteners and tools near you.

When you’re working several jobs concurrently, keeping things organized is essential to your success. Keeping tools, fasteners, and accessories in a tracking system ensures that they’re in the right place at the right time.

Using a simple inventory tracking system can reduce downtime from crews waiting and keep your projects on track.

One way to steer clear of these mistakes is to choose Grip-Rite fasteners for your jobs. Our website and packaging make it easy to find solutions to fit your application that won’t break the bank. We’re known for consistent quality across our award-winning fastener, tool, and building product lines, and you can use our products with confidence in nearly any application.

We’ve designed our packaging to include all application-specific information you might need on the job. From the basics like length, gauge, and coating to ASTM testing, our packaging tells the story.

Check out our Knowledge Center for in-depth information on how to choose the right fastener for your job.

Many of our fasteners are backed by warranties that range from 10 years to the life of your project.

Pro Tip: Always double-check packaging for application notes — Grip-Rite® labels products clearly for intended use.

Even seasoned pros make mistakes sometimes, and when they happen, it’s important to learn from them. As hard as it is to admit gaps in knowledge or mis-timed caffeine intake, owning it is the first step.

Choosing the right fasteners for your project requires understanding the parameters, application, and budget. With Grip-Rite, you can work with confidence knowing your projects can stand up against any challenge.

Find out Where to Buy Grip-Rite fasteners and tools near you.