Continuous insulation requirements for wood-framed walls in the 2022 IECC point to the enhanced performance of exterior insulation over typical cavity insulation. By preventing thermal bridging, this exterior barrier increases energy efficiency and prevents outside air from penetrating the interior.

Choosing the right continuous insulation material for a project involves more than just thermal performance; comparing each option leads to better outcomes. Different products feature components that allow moisture to evaporate, protect against radiant heat, and prevent flame spread in the event of a fire. Others are hydrophobic, pest repellent, and drainable. Projects in different climate zones benefit from specific performance features that can help determine which is best.

We’re examining the pros and cons of the most popular continuous exterior insulation products, including:

By exploring each in depth, you’ll learn about how to select the optimal exterior insulation for your climate, crew, and budget.

While IECC codes don’t require specific CI material, implementing it isn’t up for debate in many parts of the country. Manufacturers have attempted to provide a range of continuous insulation options for pros to choose from, and they’ve done their homework. Different solutions are preferred regionally, but similarities between products are easy to spot.

Semi-rigid options, such as Rockwool, are available and typically secured outside the sheathing layer with furring strips. Mineral wool drains exceptionally well and repels insects, unlike some other insulation materials. Any moisture that gets behind the cladding layer quickly evaporates or drains out through the bottom of the wall assembly.

Rigid options fall into two camps: rigid foam and insulated sheathing.

Typically, rigid foam insulation is made from either polystyrene or polyisocyanurate backed by foil or weather-resistive material. Both formulations provide adequate protection from thermal bridging, but with some drawbacks. Polyiso foam board experiences R-value drift over time, while polystyrene does not. In polyiso sheets, gaps along joints open, which can lead to a reduction in efficiency.

OSB or plywood sheathing backed by rigid foam has become increasingly common on job sites in recent years. The benefit of this application is that contractors can provide both structural sheathing and shear strength with CI. Major building products manufacturers produce high R-value sheathing with both polystyrene and polyiso.

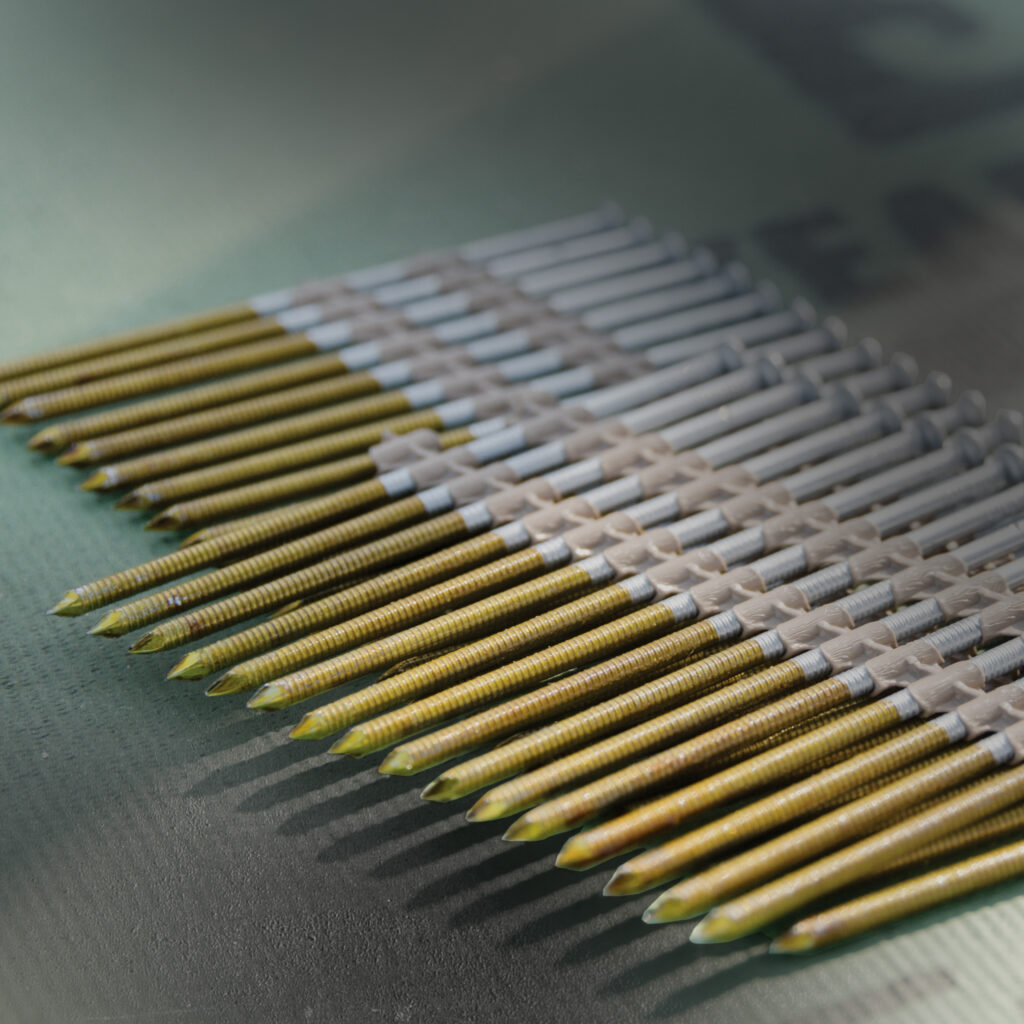

Due to the thickness of both rigid foam and insulated sheathing, fasteners have had to adapt. Hand-driven options are widespread, but an acceptable collated option hasn’t existed on a broad scale until now.

Grip-Rite SpeedSpike™ is the first widely available collated fastener for high R-value sheathing. Combining over 5x faster driving, 4-½” length for at least 2” embedment in wood studs, and a ring shank for superior hold, SpeedSpike™ is changing the game.

Foam board is one of the most common types of exterior insulation, and for good reason. These durable, lightweight products have high R-value and are easy to install. Whether fabricated from polystyrene or polyisocyanurate, they’re widely used in residential and light commercial construction projects.

What it is: Rigid plastic foam boards (XPS, EPS, polyiso). Widely used in residential and light commercial builds.

Why it works:

Field considerations:

Jobsite insight:

Semi-rigid insulation solutions like mineral wool are commonly used in wall cavities and other interior insulation applications. Made from spun stone or metal fibers, it is fire-resistant, hydrophobic, and vapor-permeable. Applied outside of the sheathing layer, it’s used in both residential, multi-family, and commercial applications.

What it is: Semi-rigid boards made from spun stone or slag fibers.

Why it works:

Field considerations:

Jobsite insight:

Insulated sheathing panels are a recent addition to CI options. They combine rigid foam insulation with OSB or plywood sheathing panels for strength and performance. Some, like Zip-R, include a factory-applied WRB for a complete, all-in-one sheathing solution. Others require the application of an additional weather resistive barrier for optimal performance.

Grip-Rite ProWrap® is the perfect complementary product for uncoated sheathing panels. Packed with high-end performance features, it serves as a three-in-one weather resistive barrier. No primer needed, just peel and stick.

What it is: Structural panels with integrated foam insulation and sometimes a WRB layer. Examples include ZIP System® R-Sheathing, LP NovaCore®, and Atlas EnergyShield® Ply Pro.

Why it works:

Field considerations:

Jobsite insight:

Different CI applications require various features and benefits for optimal performance. Contractors working in WUI (wild-urban interface) areas or in fire-prone regions require fire resistance, while those in humid climate zones need higher permeability and drainability. Builds on a budget benefit from less costly solutions, while high-end designers may spec a more expensive product.

We’ve gathered the most important features here to help you decide which CI solution is best for you. It’s not a “one-size-fits-all” situation, and your needs can help determine which material is ideal.

| Criteria | Foam Board | Mineral Wool | Insulated Sheathing |

| R-value per inch | High (5–6.5) | Moderate (4–4.3) | High (varies by core) |

| Fire Resistance | Low–Moderate | High | Varies |

| Vapor Permeability | Low to Moderate | High | Depends on the facer |

| Cladding Attachment | May require furring | Solid support | May be integrated |

| Install Complexity | Moderate | High | Low–Moderate |

| Cost Per Sq. Ft. | Low to Moderate | Moderate | High |

| Best For | Energy upgrade, cost-sensitive jobs | Fire-rated, moisture-sensitive jobs | High-efficiency, fast builds, high cost |

Code implementation varies by municipality, so builders should check with their local building inspector’s office to ensure compliance.

Selecting the right continuous insulation product for your building projects can improve energy efficiency outcomes and the longevity of the structure. Balancing the features and benefits of semi-rigid and rigid insulation solutions to your climate zone is essential to future success.

Each class of product has benefits, but tailoring the material to the environmental factors is a must. Other considerations include

Choosing the most effective solution for your crew, your climate, and your schedule matters most. Ensure you can obtain the necessary product and the required fastening system to install it when needed.

Find out Where to Buy Grip-Rite SpeedSpike™ near you.