Summer is here, and across the country, contractors are filling up their calendars with construction projects. As the high heat of July and August looms, getting big projects underway in the early part of the season makes sense.

With costs on nearly everything rising and a shortage of skilled labor, it’s vital to plan construction projects down to the last fastener. Thoughtful planning can also help maximize efficiency and reduce wasted time and resources on a build.

Grip-Rite is here to help you execute a profitable and stress-free summer construction season. We’re highlighting some seemingly small efficiencies that can have a massive impact on your calendar and bottom line.

What you’ll find in this article:

Outdoor construction projects follow a seasonal ebb and flow that varies depending on your region. Much of the country experiences milder weather in summer after a rainy spring. This makes bigger jobs more feasible, allowing contractors to fill their schedules with more profitable builds.

Typical projects that contractors undertake in the summer often involve longer timelines than those in other seasons. Depending on the region, this can include prolonged UV exposure, summer storms, and, in the Southeast, hurricane season.

Some construction projects you might see come through include:

Choose materials that can withstand the expected heat and occasional rainy afternoon without degradation. Each of these project types has some overlap in materials that you can plan for and purchase in bulk for better pricing.

Of these, decks often take the top slot as they bring the most value to homeowners in the long run. Using traditional pressure-treated wood is effective in some regions, but natural products are more susceptible to the effects of long-term exposure than synthetic materials.

Manufactured decking products are less likely to break down over time in typical use cases. New manufacturing techniques can closely mimic the appearance of real wood, so the real consideration is price. Initially, these products are more expensive; however, the long-term benefits result in savings over the deck’s lifetime.

Wolf Perspective™ decking is an excellent example of high-quality manufactured decking. Composed of 94% recycled materials, it utilizes fiber sequencing technology, which lends strength and mimics the appearance of wood. Protected from the elements by proprietary encapsulation additives, it’s a worthwhile investment.

Wolf Serenity™ decking is a premium, manufactured decking product built to perform in the toughest conditions. Rated for coastal applications with Colorwatch100® for industry-leading color retention. Available in both grooved and square profiles, it allows installers to use any fastening system.

Using the right fasteners can be the difference between a seamless building process and frustration on the job site. Furthermore, fasteners in exterior projects are exposed to environmental chemicals and moisture, which can lead to corrosion and premature failure.

High-volume contractors need a fastener that delivers reliable performance, exceptional speed, and bomb-proof corrosion resistance.

Explore our blog on exterior screw coatings for a comprehensive overview.

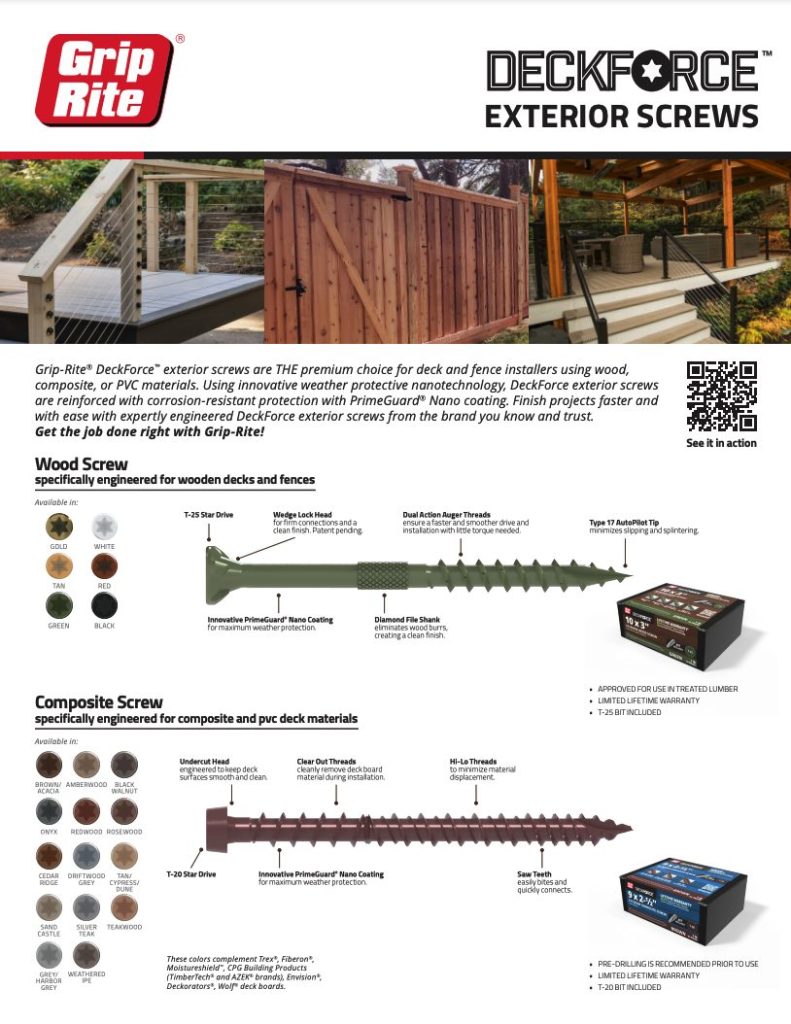

Grip-Rite DeckForce® Exterior Wood Screws are the ideal choice for contractors and builders who demand the best. Coated with industry-leading PrimeGuard® Nano, they have what it takes for high-moisture applications like decks and fences.

Drive faster with a secure star drive and AutoPilot T 17 tip that eliminates the need for pre-drilling in most wood. Features like the diamond file shank and Wedge Lock™head create a strong bond between materials.

Grip-Rite DeckForce® Composite Screws are the ideal choice for manufactured wood products and PVC. PrimeGuard Nano protects the fastener from moisture, and a T 17 Saw Tip ensures efficient material removal for a secure hold.

Application-specific Hi-Lo threads reduce the chance of stripping out composites. Clear out threads and undercut head reduce the possibility of mushrooming and create a seamless finish.

For grooved decking, the Grip-Rite Ninja® system provides a versatile and seamless system for hidden deck fasteners. Compatible with grooved deck systems like those from Wolf, Ninja includes clips, starter clips, and a bit stabilizing tool for fast and accurate installs.

Find out Where to Buy these hand drive fasteners near you.

High-volume construction projects benefit from collated fasteners when speed counts. Using either pneumatic or electrically powered tools, they allow one contractor to complete the work of several.

Grip-Rite offers a wide range of collated fasteners to help you get the job done right. Depending on your application, collated fasteners can increase your volume, speed, and overall efficiency.

Typical summer jobs, such as fencing, siding, and outdoor building projects, can all benefit from collated fasteners.

Check out the full lineup of Grip-Rite collated fasteners.

While a hammer and screw gun go a long way towards helping contractors complete summer projects, pneumatic tools accelerate the process. These tools use compressed air to drive fasteners with more efficiency, accuracy, and speed.

Here are a few options you may want to consider adding to your arsenal.

Framing nailers are engineered to install heavy-duty fasteners for load-bearing applications. Consider them if you’re building decks, framing out residential projects, and the like.

Grip-Rite has three framing nailers in our current lineup that address these applications.

While you’ll get the same result with any of these framing nailers, there are some slight differences. Plastic strip collation is more durable than paper tape, and coil magazines are shorter than traditional ones, making them ideal for tight spaces.

Fencing and siding nailers are engineered to work fast and accurately, firing lightweight fasteners with adjustable depth. Consider these if you’re building fences or repairing/replacing siding.

Grip-Rite has two options in our current lineup for these applications.

Attaching house wrap and roofing underlayment with a hammer tacker puts unnecessary strain on your team. Including a pneumatic plastic cap stapler increases your efficiency and reduces the rate of tear-through.

Grip-Rite offers one tool for this application.

Powering pneumatic tools requires an air compressor and hose system. You’ll want to tailor the size of your compressor to match the type of job you’re on. Some projects require maximum capacity, others maximum portability.

Grip-Rite offers a range of compressors to suit the size of your job and crew.

Grip-Rite compressors, tools, hoses, and accessories comprise the RED System, which is backed by a 7-year, industry-leading warranty and service program. With fast nationwide service, we’re committed to keeping you on the job.

Wondering Where to Buy Grip-Rite Compressors? Click here to locate the nearest dealer.

With the right fasteners and tools in place, you can tackle your summer construction schedule with confidence. We’ve got a few more tips to help you keep your crew on schedule as temperatures begin to climb even higher.

These tips can help you keep your crew ready and productive, no matter the size of the job.

Grip-Rite fasteners and tool systems are exactly what you need to be ready for summer construction contracts. For maximum efficiency with the results you demand, get the job done right with Grip-Rite.

Find out Where to Buy Grip-Rite near you.