Pros know that moisture is the greatest threat to any home, and flashing tape protects a home’s weakest link. Windows and doors are among the most common points in a building’s envelope where water can seep in. Properly applied around these rough openings, flashing tape can preserve building envelope performance while protecting the built environment from water damage.

In recent years, we’ve seen the development of liquid flashing, modified asphalt flashing, acrylic flashing, and butyl flashing. Each of these adhesives has its pros and cons, depending on how well it adheres to various building materials.

Flashing tape is typically comprised of three different layers: facing, membrane/adhesive, and backing. Manufacturers produce a variety of flashing tapes with unique combinations for HVAC, decking, and building envelope applications. You might use an aluminum tape for ductwork, copper tape for decking, and polypropylene or polyethylene-faced tape for building envelope applications.

Adhesive layers also vary, ranging from SBS modified bitumen to acrylic and butyl. Each has its pros and cons, which affect where and at what temperature the flashing tape adheres best.

Backing is either one piece or split back. Depending on the width of the tape and the strength of the adhesive, a split back makes application easier.

We’re focusing on the building envelope for this article and will examine how our line of ProWrap flashing tapes performs when applied around window and door openings.

One of the most important considerations when discussing flashing around window and door openings are code requirements.

According to IBC Section 1404.4 and IRC R703.4, flashing must be installed in all window and door openings to direct water out to the wall or WRB for drainage. This applies to mechanically applied flashing, fluid applied flashing, and self-adhering flashing. Materials must meet or exceed the testing standards listed in AAMA 711 to comply with code requirements.

Self-adhered flashing tapes that meet adhesive bond strength, sealability, weathering tests, and thermal exposure can increase the longevity of a project. They must also be connected directly to the weather-resistive barrier or wall finish to prevent water from penetrating the wall cavity.

Because window flanges are nailed through flashing, self-adhering tapes must provide self-sealing qualities to prevent leaks. Further, they should be able to withstand extreme temperature shifts without cracking or delaminating and maintain pliability in cold weather.

Without these tests, it’s impossible to know the performance properties of flashing tapes over time. Using a product that doesn’t meet the standards can result in severe damage to a home or business.

Grip-Rite ProWrap® FLEX and Butyl flashing tapes both perform at or above the AAMA 711 standards.

In an ideal build process, your crew would install windows and doors as soon as they apply flashing tape, protecting it from exposure to the elements. That said, we know most processes aren’t ideal, and stretched-thin crews may not install them for days or weeks after. This period of exposure tests the performance and resilience of flashing tapes, potentially causing damage and leaving openings susceptible to future leaks.

Common field conditions that stress flashing tape performance include:

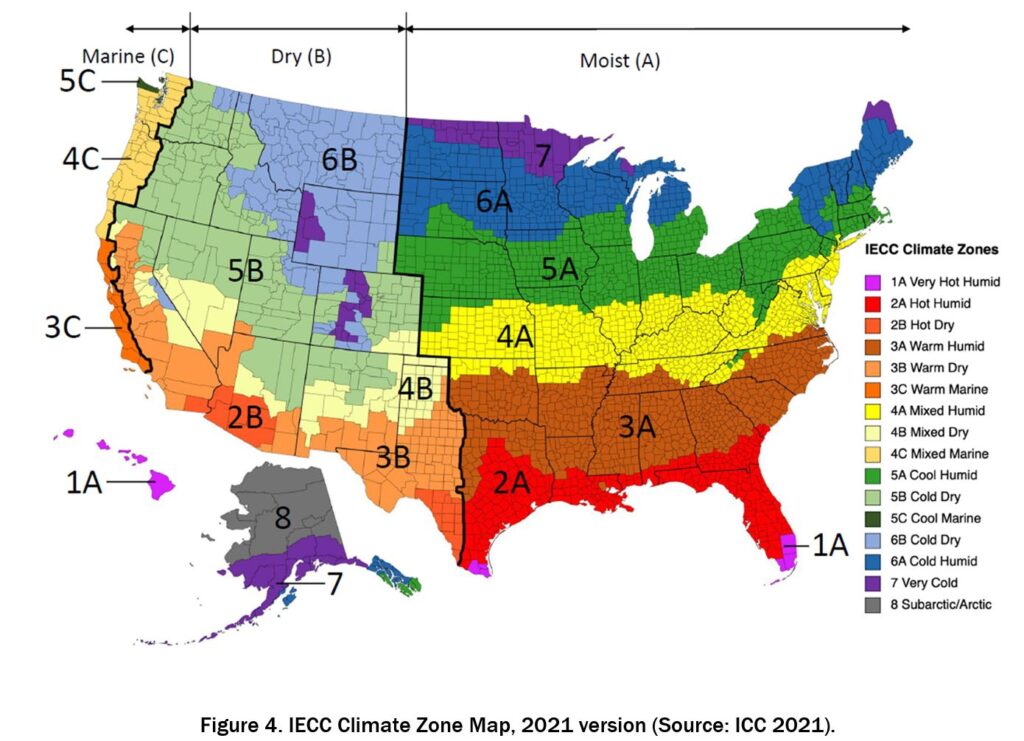

In addition to these universal environmental factors, regional climate variations put flashing tapes to the test. Combinations of temperature and humidity shift dramatically from Climate Zone 2 to Climate Zone 8. Tape performance shouldn’t suffer from one to the other.

Balancing the right materials can make all the difference in how tapes fare regionally. Adhesives can lose their stickiness in extreme cold or crack, metallic facing can delaminate, and cracks allow moisture to enter. By including a primerless, flexible butyl adhesive in our flashing tapes, Grip-Rite ensures uniform performance, regardless of where the build falls on the climate map.

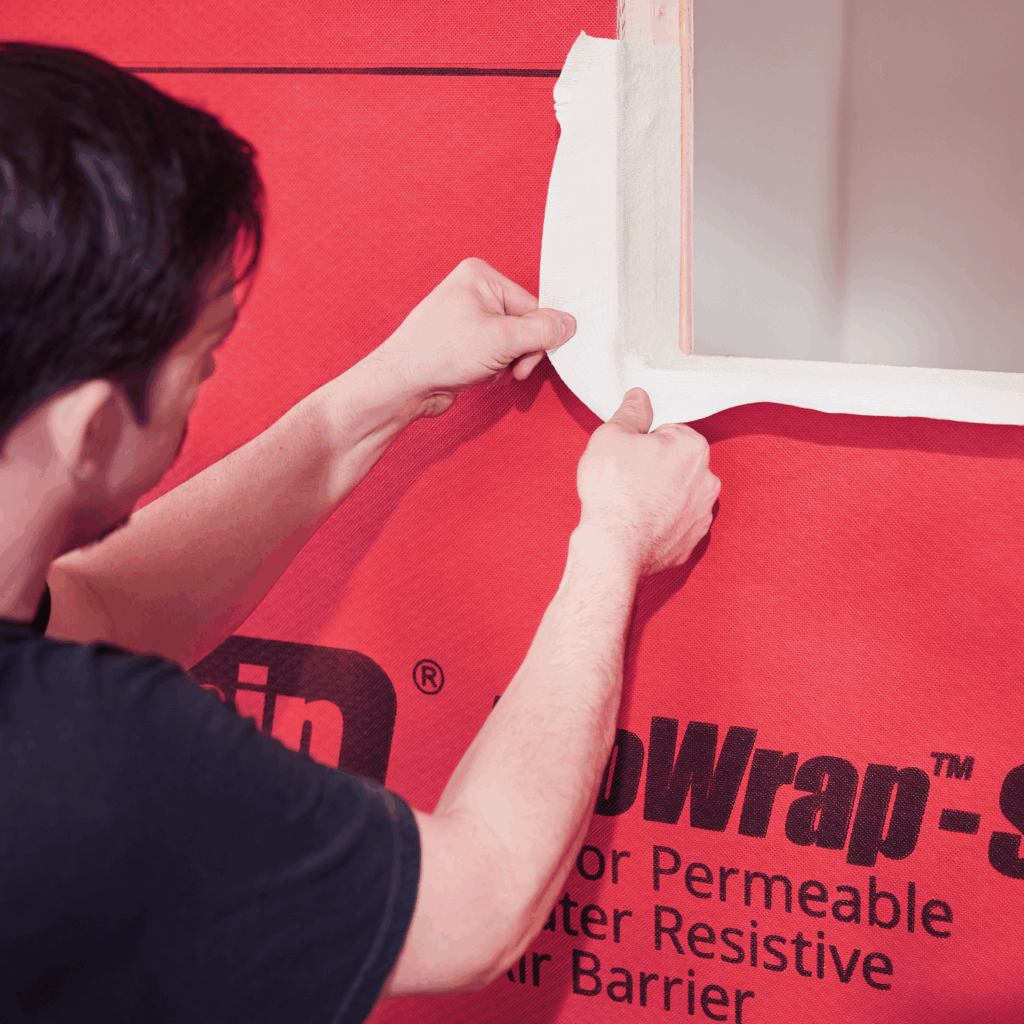

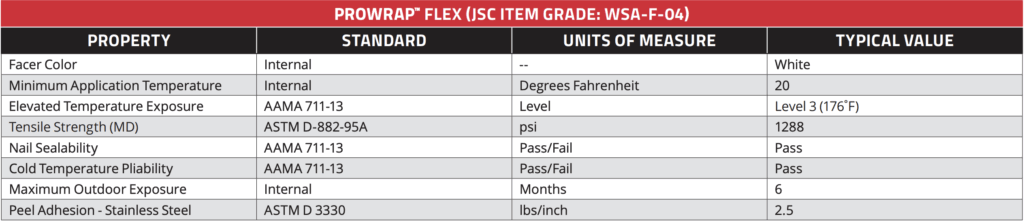

ProWrap® FLEX is a conformable flashing tape intended for use on bottom sills and sill plates. Once released from the backing, it molds easily to corners, curves, and other uneven surfaces. FLEX allows you to preserve the continuous air and water barrier that’s integral to modern HVAC systems.

Fast Facts:

FLEX works as part of a layered system with Butyl flashing tape and ProWrap®-SA weather-resistive barrier.

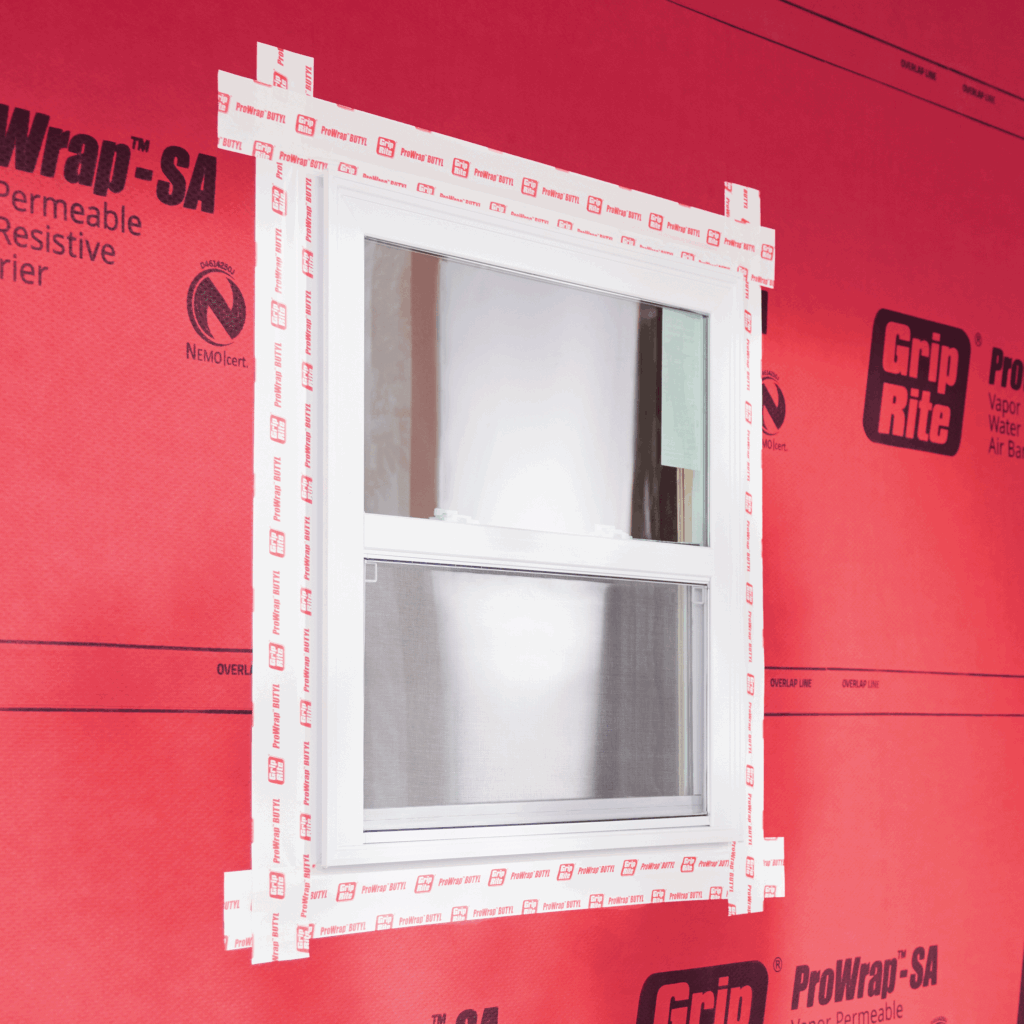

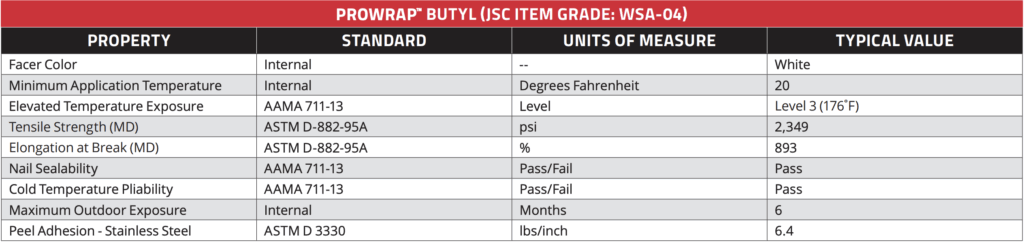

ProWrap® Butyl is the workhorse of Grip-Rite’s flashing tape lineup. Designed for linear runs and as part of a layered, integrated system for extreme weather protection. Conformable to a variety of surfaces and openings, it adheres easily to most common construction materials (wood, brick, concrete, and metal) without a primer.

Fast Facts:

Installed as part of the ProWrap® system, Butyl preserves the continuous air and water barrier integral to contemporary home construction.

Grip-Rite ProWrap® is an award-winning integrated WRB system that gives pros peace of mind when completing a build. Innovative materials make ProWrap®-SA a best-in-class membrane with >90% drainability and peel-and-stick convenience. Paired with FLEX and Butyl, ProWrap® protects every build with a leak-proof barrier that still allows vapor from inside to dry outward.

There are plenty of flashing tapes on the market, but using the ProWrap system ensures superior performance and easy sourcing.

Using these products together provides even greater benefits through the Grip-Rite PROtection system, which offers an industry-leading 15-year warranty. Pros using ProWrap®-SA can combine with ProWrap FLEX and Butyl and Franklin Titebond® WeatherMaster for a robust seal.Learn more about how the Grip-Rite® PROtection system works to keep your projects strong.

Flashing tape preserves the air and water barrier that’s so important for modern home systems to function. While testing helps ensure a baseline performance level for all tapes, there are distinct differences among manufacturers. Choosing the right one for your application means considering adhesive, facer, and substrate.

Grip-Rite ProWrap® flashing tapes are designed for extreme temperatures and performance. Codes set the baseline, but Grip-Rite® sets the bar.

Find out Where to Buy ProWrap® flashing tapes near you.