Weather resistive barriers (WRBs) play an integral role in the building envelope. These synthetic membranes provide water resistance while still allowing airflow and vapor transfer from the interior of a structure.

Choosing the right WRB for your project requires balancing features and cost. Residential structures have different requirements than large commercial buildings; knowing which products address them is essential.

We’re looking at the most common types of weather resistive barriers today. We’ll look at applied WRBs and different applications where they’re used.

Let’s roll!

Before we discuss the role and function of WRBs in the building envelope, let’s review the concept. From below-grade basements to the roof peak, the building envelope is the exterior layer of protection from the elements. It combines several products in the wall assembly to protect the interior from unwanted vapor and water infiltration, providing a healthier, more stable interior environment.

Engineers compose wall assemblies to work on four control layers: water, air, vapor, and temperature. Of the four control layers, house wrap products can positively affect all of them. This wasn’t always the case with WRBs.

In older housing stock, felt paper often served as the primary WRB in the wall assembly. While builders used this product for generations, it wasn’t nearly as effective at moisture management as new-generation products. It tore easily, degraded quickly under high winds and UV exposure, and became brittle in colder temperatures. The benefits of modern WRBs over felt paper are clear for contemporary structures.

Builders frequently work towards a tight building envelope that allows very few air leaks. Instead of allowing outside air to balance inside humidity, they rely on active and passive methods to help keep levels consistent.

Active methods use power to ensure interior spaces and wall cavities don’t experience high humidity that causes mold and rot. However, power isn’t always reliable in extreme weather events, and systems fail. Having a passive system in place is an essential step to prevent damage from unexpected circumstances.

As passive systems, weather resistive barriers play three key roles in preventing moisture buildup in a structure.

A well-engineered product will keep rain and water out, promote evaporation of moisture that makes it into the wall assembly, and allow a structure to breathe.

In recent years, the building products market has seen a surge in two types of WRBs: applied and integrated weather resistive barriers. Integrated WRBs are typically exterior sheathing systems that include OSB pre-coated with a fluid-applied product. Combined with taping, they’re a popular choice. They’re not the right fit for every project, though, and only make up a small portion of the overall market.

Applied WRBs are much more common. They’re typically either mechanically applied or self-adhesive and provide varying levels of protection to a structure.

Housewrap is one of the most commonly used WRBs today. It’s generally either woven or non-woven and is mechanically applied using staples or nails directly on the sheathing. Manufacturers use a synthetic substrate as the base material and then coat one or both sides with low-density polyethylene (LDPE) for enhanced water resistance.

Drainable housewrap has the same qualities as regular housewrap with enhanced drainage. Products in this category include raised bumps on the outer face of the housewrap to allow water to drain downwards. This ensures that bulk moisture doesn’t sit in the wall assembly and cause damage.

Fluid-applied WRBs are painted onto sheathing to provide a seamless barrier against the elements. Rolled, brushed, or sprayed onto the outer face of sheathing, fluid-applied membranes create a continuous air and water barrier. Deployed correctly, this WRB creates a tight seal around protrusions and complex areas of the outer sheathing.

Self-adhered WRBs combine traditional housewrap permeability and drainage features with the convenience of fluid-applied products. This is a growing segment of the housewrap market because of high-performance features and simple application.

Grip-Rite offers a comprehensive lineup of mechanically applied and self-adhering housewrap products. We’ve incorporated the latest technological advances in WRBs and included some of our own to make our products the best in class.

Designed for residential projects, Grip-Rite House Wrap-LWE combines powerful features with an economical price point. It prevents moisture penetration from outside the wall assembly while allowing vapor inside to escape. The transparent fabric makes this mechanically attached house wrap easy to install.

Grip-Rite WeatherResistor-HP is a non-woven house wrap with premium features in a lightweight product. This mechanically attached weather resistive barrier has a high permeability rating to keep interior moisture under control. With 98% drainage efficiency, this house wrap directs water away from the wall assembly for efficient drying.

Grip-Rite Commercial Grade-D wrap is a heavy-duty, mechanically installed WRB with a cross-woven polyethylene fabric structure. This weather resistive barrier provides robust protection against severe rain, snow, and wind-driven rain to protect the wall assembly. Intended for use in commercial projects.

Award-winning Grip-Rite ProWrap-SA is a self-adhering, spun-bonded polypropylene WRB that doubles as a 2-in-1 water-resistive and air barrier. Using a powerful butyl adhesive, this house wrap is easy to install with a rock-solid hold. It promotes a continuous weather barrier when combined with Grip-Rite ProWrap Butyl window and door protector tape.

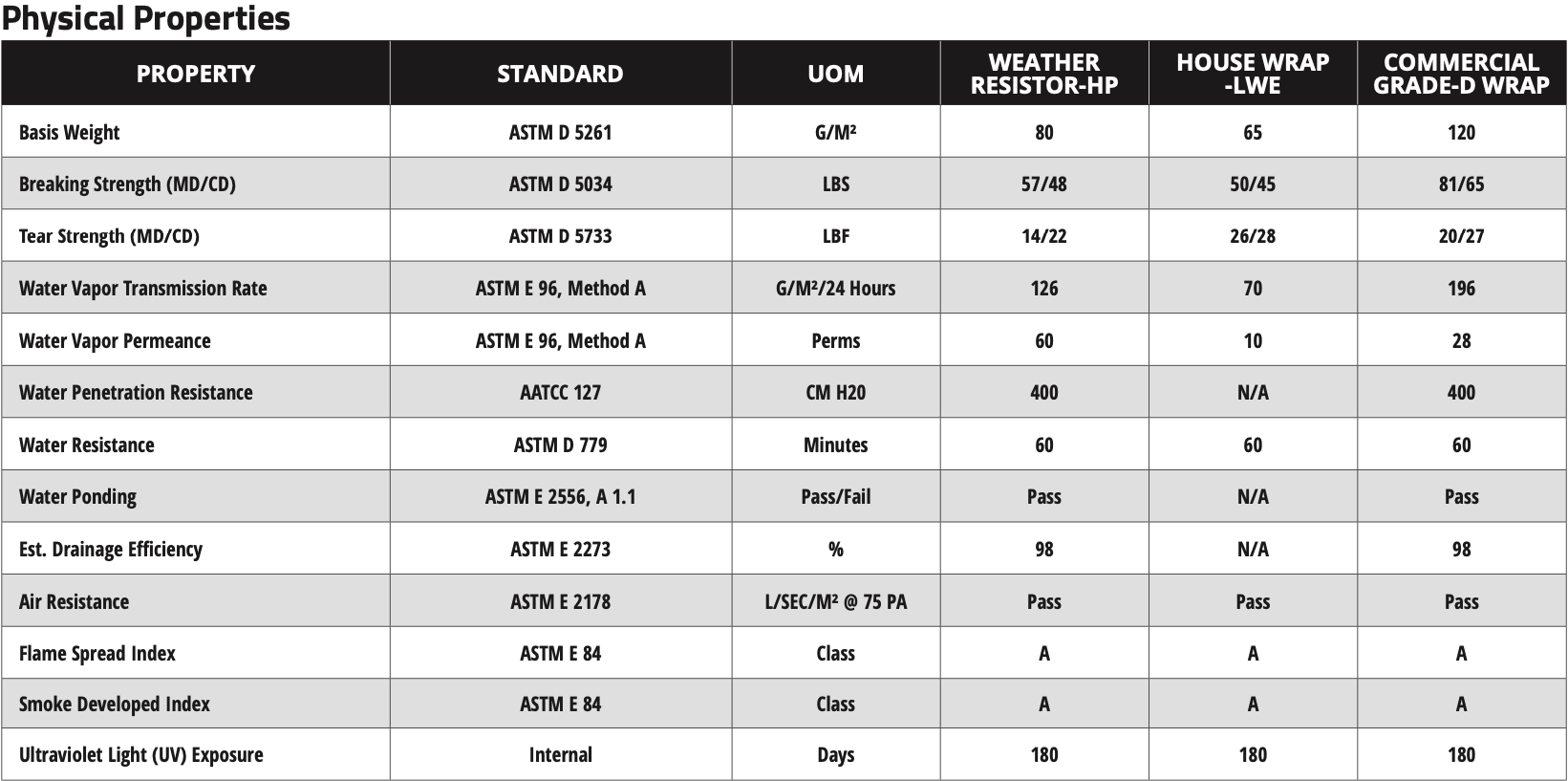

When addressing the needs of a specific project, the right weather resistive barrier is usually dictated by code. Commercial building codes are typically more stringent than residential, and so WRBs intended for commercial construction are thicker with enhanced performance benefits. As you can see from the table, Commercial Grade-D is almost twice the weight of House Wrap-LWE, stronger, and with higher water and vapor performance across the board.

Grip-Rite offers an industry-leading 15-year warranty program[PDF] for contractors who install one product from each of these three categories:

When you use Grip-Rite weather resistive barriers, you install a brand you can count on. Through exhaustive testing and research, our team ensures each product in our lineup meets the most stringent standards.

The most efficient building envelope integrates future-forward house wraps into its design for superior water, air, vapor, and temperature control.

Find out where to buy Grip-Rite near you!